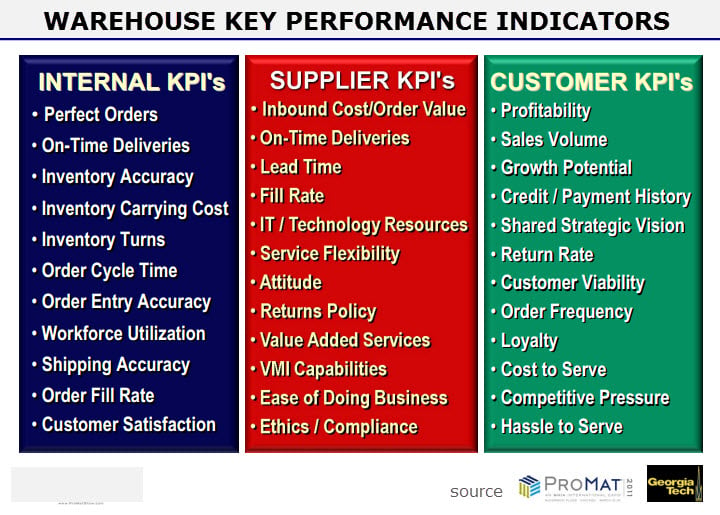

As a forward-thinking manager at a warehouse, a distribution center, or in a manufacturing plant, you know the importance of orchestrating, sustaining, and leading a state-of-the-art work environment for your team, your vendors, and your customers. You strive to create a system that is not only well-organized and highly-efficient, but also safe and waste-free. While there are lots of variables that contribute to creating such an operation, one integral factor directly contributing to the success (or demise) of your facility is the work ethic of your order pickers.

From A to Z, here’s a look at the order picker job description: the ideal qualities, characteristics, and skills of top-of-the-line order pickers: