5S is a philosophy, a way of thinking which focuses on organizing and managing the workspace by eliminating 7 Wastes while improving quality and safety.

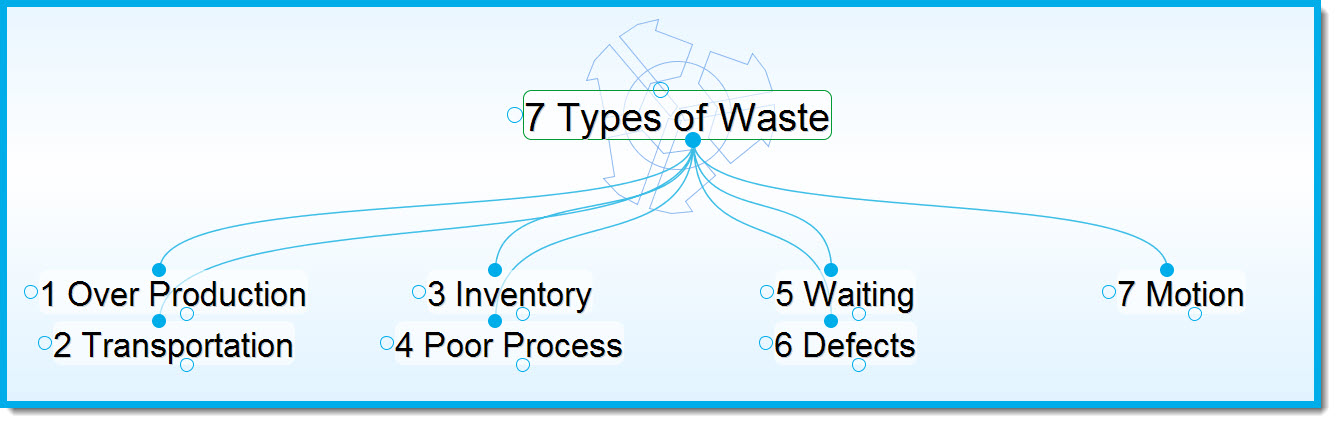

Waste:

Muda (無駄) is a Japanese word meaning "futility; uselessness; idleness; superfluity; waste; wastage and wastefulness". A process that consumes resources where waste occurs is when more resources are consumed than are necessary to produce the goods or provide the service that the customer actually wants.

There are forms of waste in addition to the seven. The 8 most common forms of waste can be remembered using the mnemonic "DOWNTIME"

- Defective Production

- Overproduction

- Waiting

- Non-used Employee Talent

- Transportation

- Inventory

- Motion

- Excessive (Over) Processing)