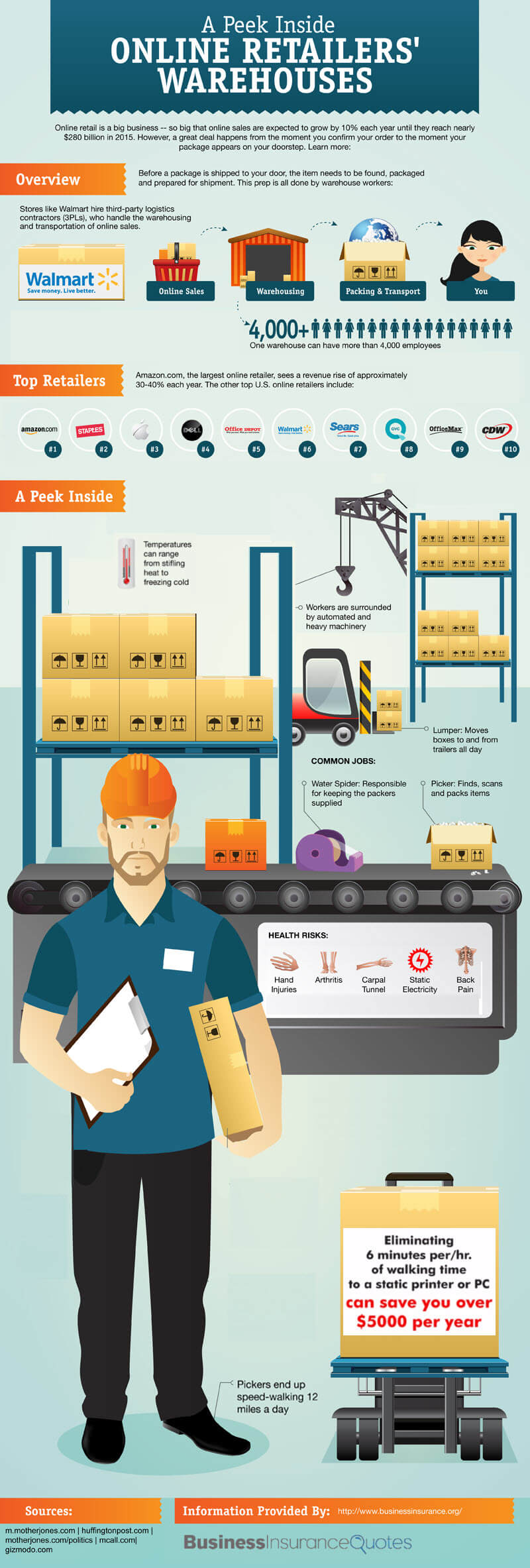

Mispicks in the order picking process can be easily defined and understood. Order picking is the process of pulling items from inventory in the warehouse to fill a customer order. However, eliminating mispicks is a costly and ongoing dilemna.

In fact, distribution centers are losing an average of nearly $390,000 per year due to mis-picks, according to a study conducted by Intermec, Inc.