While many industries rely heavily on communication to ensure that things run smoothly, nowhere is it more crucial and more layered than in manufacturing. Keeping everyone in the loop from those on the floor to management overseeing everything is imperative to make sure that everything runs as smoothly as possible, but even with technology making our communication easier than ever before, there are still some interesting trends that indicate we still have a long way to go.

Today we’ll look at what is happening in the world of manufacturing and where it communication processes will go into the future.

What are Problems Facing Manufacturers Today?

Although technology is enabling many companies to integrate services and features that would have otherwise been impossible before, there are still a lot of gaps in the way they communicate in-house and with everyone in their supply chain. Although integration is still the best way to go, one of the biggest problems is that no single communication device can do everything.

For example, a mainstay of operational management is still the two-way radio. Even if the era of the smartphone, this technology is still the go-to for many businesses as a way to connect everyone seamlessly. In fact, according to recent research, usage of radios has gone up by thirteen percent in the last couple of years.

Unfortunately, while the radio is still the number one method for employees and management to reach each other, smartphones and tablets are also much more ubiquitous, which means that most floor staff have to carry and manage multiple devices on the job. This means that they can potentially be making calls on a radio, then switch to a phone for a text, and then enter data on a tablet.

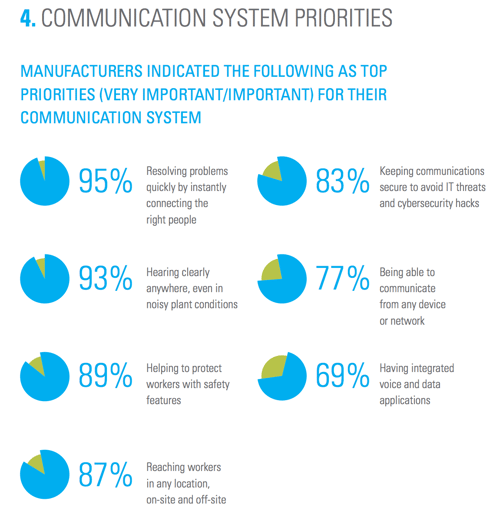

As a result, companies are looking for new and innovative ways to streamline their communication abilities so that employees don’t have to manage so many different things all at once. Here is a breakdown of the top three things that manufacturing companies value as far as communication.

- Reaching anyone at anytime

- Clarity of calls and messages

- Protecting workers with safety features

So, it’s obvious that it’s important for any communication system to be comprehensive and reliable above all else. What that also means is that while radios are perfect for in-house communication, smartphones are still necessary to reach anyone outside of a certain radius.

Issues With Hardware

Knowing the points that are most crucial to operations, there are still some hurdles that have to be overcome to get to a point where everyone gets what they want. First of all, getting reception in a factory or on the floor is not always possible, especially with sensitive smartphones that require a satellite signal.

Second, many of these devices are fragile, so if they are dropped or fumbled, then they might break and need to be replaced. Third, not all services may work, such as internet or data, which can cause problems out in the field. Finally, battery life is always an issue, as mobile devices tend to run dry much faster than older systems like walkie-talkies or radios.

Digital Radios: The Solution?

These days, since a two-way radio is still the most efficient and effective method for quick and

reliable communication, many companies are switching to digital versions so as to combat the most common problems and ensure a better workplace for all. Here are some of the main reasons that the switch to digital is happening at a record pace

- More functionality

- Lower downtime

- Improved safety

- Fast response time

- Automated processes

- Data operations

So why are these becoming the go-to option for most manufacturers? Well, the biggest reason is that it combines the best features of analog radios with the added functions of a smartphone. This way, instead of having to carry two devices, staff members can have only one.

One important feature of a digital radio is that you can program it to fit your needs. For example, with regard to worker safety, an employee can hit a button that sends out an emergency signal that they need help. This ensures prompt response and less downtime as a result.

Another great thing about these devices is that they can be used for group communications with the same level of response as an analog version. As we saw above, clarity and the ability to reach anyone at any time were the top two issues that needed to be addressed, and digital radios seem to provide excellent results in both categories.

The Future of Communication

While digital radios are a great choice for companies looking to improve their bottom line, the next step will be to integrate them into data collection and transmission.

For the most part, staff still has to use a tablet or chip reader to log information regarding inventory and tracking, which means that there are still multiple devices being used at the same time. Thus, we think that if anyone can create a device that can do everything quickly and efficiently, that will become the default component of any operations.

When you think about it, the more that you can integrate solutions and consolidate devices, the better off everyone will be. If you can call your manager on the same machine that you use to scan RFID tags, and you can also use it to track inventory via GPS, and it syncs up to the company’s backend system, then that will make things so much easier for everyone. As such, we believe that that kind of integration will be the next big thing in manufacturing communications.