When proposed with the option of stand alone warehousing versus an integrated operation of warehousing and distribution, many managers today shrug at the notion of added responsibilities. So, they continue on with their typical approach, and the end result is profit reduction and dissatisfied customers.

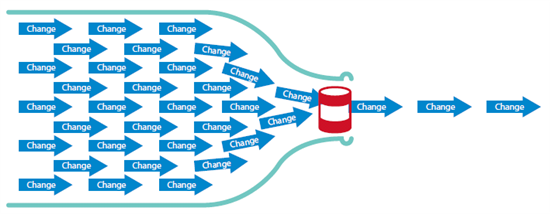

While this is not an across the board occurence, it is commonplace enough to bear consideration of a new way to view housing and distributing inventory. The profit reductions can occur as a result of one segment, i.e. the warehouse or distribution, focusing their attention on what only they can control at the expense of other functions of the supply chain. This creates an avalanche of cost increases ultimately impacting the end customer, thus lost revenue.