Warehouse construction boomed alongside eCommerce during the height of the COVID-19 pandemic but slowed shortly after. Now, we’re witnessing new, more sustainable growth and higher spending in warehouse automation that is expected to carry into 2024--here’s what’s happening.

The Pandemic Effect on eCommerce

It’s no secret that eCommerce activity soared in 2020 due to the COVID-19 pandemic. According to a U.S. Census Bureau study, eCommerce grew 43% in one year alone as consumers chose to purchase nearly everything online, from clothing to household goods to food.

Over three years later, online shopping is still going strong. While many people have returned to retail outlets for some items, eCommerce still accounts for roughly 20% of all shopping worldwide. And that figure is expected to hit 30% by 2040.

In addition to buying more items online, consumer expectations have soared.

Customers want packages on their doorsteps in record time and have become accustomed to sellers offering regular deals, such as Summer sales, Fall sales, and mid-week sales. Online businesses are understandably struggling to keep up.

Warehousing Trends — Higher Spending on Automation Solutions

At the height of the pandemic, eCommerce sellers were forced to respond quickly to these new conditions, which also included massive supply chain disruptions. According to the Federal Reserve’s’ Global Supply Chain Pressure Index (GSCPI), supply chain disruptions peaked in 2021 and eased into 2022.

Part of the relief was due to actions taken by sellers to ease their challenges in responding to heightened consumer demand. Many businesses chose to invest heavily in warehouse construction and various automation solutions. While some ports were closed to international shipments and workers were unable to help for a variety of reasons, businesses that had put off investing in automation and new space decided to take the plunge.

The Warehouse automation market grew by an impressive 28% in 2021, largely driven by spikes in eCommerce demand. Some warehouses overplayed their hands to an extent by building up too much capacity, which turned into a hardship as the global economy struggled in 2022.

The Future of Warehousing & Fulfillment

The pandemic and other global factors also had a severe economic impact on consumers and the retail industry. Because interest rates have soared and margins have become tight, many businesses slowed growth plans over the past year.

Many eCommerce businesses also assumed that consumers would permanently alter their shopping habits. While many have discovered the joys of online shopping, there has been somewhat of a resurgence in brick-and-mortar retail over the past year, catching many stores off guard.

Many eCommerce businesses also assumed that consumers would permanently alter their shopping habits. While many have discovered the joys of online shopping, there has been somewhat of a resurgence in brick-and-mortar retail over the past year, catching many stores off guard.

Due to consumers changing preferences, Amazon announced it would slow its expansion plan, with Ocado in Europe following suit. That said, retailers still need warehouses, and consumers have begun using hybrid models (Buy-Online-Pickup-In-Store) with increased frequency. Now that economic conditions have improved, businesses are projected to continue investments in warehousing space and automation in the coming years.

Leveraging Automation Solutions in the Warehouse

Some of the primary drivers for investments in warehouse automation solutions are labor shortages, efficiency and productivity gains, safety, cost savings, and the customer experience. Here are some of the most prevalent automation investments in the warehousing industry.

1. Warehouse Management Systems (WMS)

A robust warehouse management system is often the first thing many businesses implement. And for good reason. This type of system can manage and drive many automation solutions as well as track progress. A WMS can manage inventory, direct order fulfillment, and integrate with other supply chain partners to deliver increased visibility throughout the supply chain.

A robust warehouse management system is often the first thing many businesses implement. And for good reason. This type of system can manage and drive many automation solutions as well as track progress. A WMS can manage inventory, direct order fulfillment, and integrate with other supply chain partners to deliver increased visibility throughout the supply chain.

2. Automated Identification and Data Capture

Most warehouses have already implemented some form of automated data capture system. Barcodes remain popular, but RFID tags can be read without human intervention. And they can be read by RFID tag readers in bult, providing real-time data about products moving through the warehouse.

3. Autonomous Guided Vehicles

The market for autonomous guided vehicles was already expanding by more than 30% before the pandemic. These AI-powered forklifts and other vehicles can move about the warehouse to put away inventory and handle other heavy-duty or repetitive tasks.

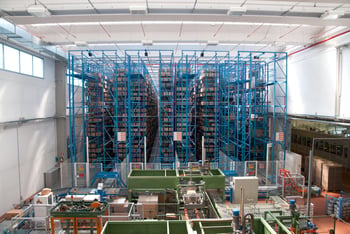

4. Automated Storage and Retrieval Systems (AS & AR)

Until recently, about 90% of warehouse picking was done manually. Today, various solutions are making this process easier and less error-prone. Automated storage and retrieval systems use a combination of racking, shelving, and pallet storage with robotics to put away inventory or pull items from shelves.

Until recently, about 90% of warehouse picking was done manually. Today, various solutions are making this process easier and less error-prone. Automated storage and retrieval systems use a combination of racking, shelving, and pallet storage with robotics to put away inventory or pull items from shelves.

5. Wearables for Automated Picking

Many warehouses aren’t ready to bring in the robots yet. But, they will adopt automation solutions that can assist human workers. For example, wireless headsets can provide pickers with directions for pulling products from shelves.

6. Drones

It will still be a while before drones are delivering packages to consumers. But, drones in the warehouse can monitor inventory, provide security, and help search for equipment or materials.

7. IoT Analytics

Sensors throughout the warehouse deliver invaluable data that helps businesses make adjustments in processes and take advantage of opportunities for improvement. This data can also help businesses anticipate and react to market changes, lessening the risk of economic hardships.

Believe it or not, a majority of businesses still aren’t using the automation tools available. According to DHL, 80% of warehouses still manually operate with no supporting automation despite the many solutions available.

Long-term eCommerce revenue growth is expected to accelerate, necessitating the need for greater productivity and efficiency. According to market research firm Interact Analysis, we can expect double-digit growth rates in automation by 2025. In addition, warehouse construction growth will fuel demand for automation solutions over the next two years.

Sellers and warehousing partners will continue to invest in optimized space as well as automation solutions to improve efficiency in the fulfillment process.