Peak season is officially here. And, if your warehouse can manage its inflows and outflows efficiently during the busiest time of year, it should be smooth sailing during those other months. Knowing how to best run your operations when the stakes are highest might be challenging. But it will also improve your overall business results.

Consumer and client expectations have never been higher. Even with supply chain troubles worldwide, everyone still wants their stuff to show up as fast as possible, affordably, and with little to no mistakes.

If you want to continue to grow your business, you’ll need to rise to the challenge. You can accomplish this by maximizing your warehouse efficiency for peak season and beyond. Here here are several ways you can get this done.

1. Optimize Warehouse Layout

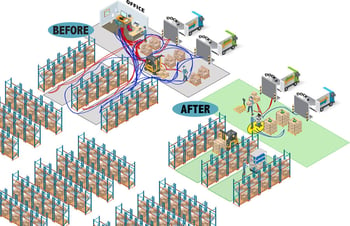

When peak season arrives, every inefficiency in the layout of your warehouse will become a glaring issue. While it makes sense to design your warehouse correctly from the start, not everyone has this luxury. And things change over the years, so it might be time to address some new operational challenges that have recently appeared.

When peak season arrives, every inefficiency in the layout of your warehouse will become a glaring issue. While it makes sense to design your warehouse correctly from the start, not everyone has this luxury. And things change over the years, so it might be time to address some new operational challenges that have recently appeared.

The most efficient warehouse layout considers movement in and out of the building as well as storage concerns. Using the data you have on hand, you can design your warehouse so that the most ordered goods are closest to the receiving and shipping areas. It’s also important to get rid of clutter to improve accessibility to stock and equipment.

2. Improve Warehouse Storage

One of the foundations of warehouse efficiency is ensuring there is a place to put everything. You need to be able to easily store, pick, and ship items as needed. This can be a challenge during peak season when the demands of your customers skyrocket.

One of the foundations of warehouse efficiency is ensuring there is a place to put everything. You need to be able to easily store, pick, and ship items as needed. This can be a challenge during peak season when the demands of your customers skyrocket.

To maximize your warehouse space, you have several options. First, you can use the vertical space you have to open up more storage. You can narrow aisles as needed to create more shelf space and make sure you are using all of the depth available. Some solutions include sliding shelves and marked containers to make product identification simple.

3. Leverage the Right Warehouse Technology

Whether you manage one warehouse or several affiliated ones, you know that communication and coordination are essential to efficient operations during peak season. They can also be some of your greatest challenges.

But you can boost efficiency within your warehouse and provide greater visibility throughout the process with the right warehouse technology. Some examples of warehouse technology solutions you can implement include:

- Cloud-based Warehouse Management System (WMS)

- Bar code and RFID tags

- Mobile-powered carts

- Automated picking tools

4. Implement an Automated Replenishment System

If you’re relying on human beings counting items or spreadsheets to keep your warehouse fully stocked during peak season, you’re probably going to run into some issues. First, these methods are inefficient, and they invite mistakes. Second, we’re in the midst of a global supply chain crisis. So, what used to take a few days and cost just a little to ship may now take weeks and cost much more.

Most modern warehouses now use a warehouse management system (WMS). This is an integrated system for managing just about every aspect of your warehouse. When it comes to your inventory, you can set specific thresholds that will automatically trigger replenishment orders. This will eliminate any troubles with backorders or unnecessary carrying costs during the busiest time of the year.

5. Streamline Picking and Packing

Order picking and packing are specific, repetitive tasks that take place in every fulfillment warehouse. They are also some of the biggest expenses, often accounting for more than half of operational costs.

Order picking and packing are specific, repetitive tasks that take place in every fulfillment warehouse. They are also some of the biggest expenses, often accounting for more than half of operational costs.

Order pickers alone spend about half of their time walking warehouse aisles retrieving items. That’s why it’s critical to examine various picking strategies that can streamline this process.

The right inventory management system combined with mobile carts and bar codes or RFID tags can speed up this process significantly.

There are a variety of strategies (ex. - zone, discrete, wave) to improve the picking and packing processes during peak season. When combined with technology solutions, cluster picking is an efficient choice. In this scenario, the worker can pick more and walk less as they make just one pass through an area to pick many orders at once.

And the same technology solutions can ensure that there is an audit trail for items being packed, increasing the level of quality control in the warehouse.

6. Create Better Receiving Processes

Another area you can take a look at for improvements is in receiving. Specifically, the way your warehouse receives goods is vital to the efficiency of the entire operation. If you aren’t putting them away quickly, they won’t be available for picking and shipping.

First, you need to be well-staffed during peak periods. This requires having visibility in your supply chain so that you know when major shipments are scheduled to arrive. With the right data, you allocate resources to ensure you can handle major shipments.

It’s also a good idea to review your receiving process to eliminate any trouble spots. Is there adequate storage in the receiving department for incoming shipments? Do you have mobile technology that can be allocated for processing items as they enter the warehouse?

7. Manage Your Returns

As activity in your warehouse goes up, so will return volume. If your clients are dealing with frequent product returns, they probably expect you to handle those, even as you are working through other peak season issues.

You can create a seamless return process that safeguards your profitability and labor hours. When returns come in, make sure they are marked as such and go to a specific area. Have a small team sort through the items and mark them as: damaged, good for restocking, or needing further evaluation.

When using bar codes or RFID tags, warehouse workers can save time processing returns. These solutions can keep track of items coming back into the warehouse and either into circulation or someplace else.

8. Offer Employee Incentives

Labor has been an ongoing issue for most businesses over the past year, and warehouses are no different. But, with peak season arriving, it’s vital that you keep your workforce as a primary consideration.

Of course, you want to keep wages under control. But not paying enough can send many workers to the competition. One solution is to offer your workers incentive pay for efficient and high productivity.

Every warehouse has a variety of opportunities to improve its operations and become more efficient. Some involve changes to processes, allowing the business to become more organized and streamlined. When combined with the right warehouse technology solutions, there is even greater potential for long-term cost savings and improved results.