The Real Meaning of “Future” - One thing that everyone hates to admit about “future articles” is that the reality of what they talk about is already here. The rest of us are behind the curve trying to catch up! While we are assigning these innovations to the “future” - perhaps to give us more time to budget for them – it certainly doesn’t hurt to invest our time into learning our options and planning ahead for the opportunity to take the leap with something new.

Today we’ll cover a few themes in the future we see recurring across different industries:

- The “Internet of Things”

- The Future of Software in the Warehouse

- The Evolution of Warehouses into Distribution Centers

- Resource Scarcity – Space and People

There are things on the list that will seem familiar at first sight, but the specific applications being conceived of and deployed include some truly innovative and compelling solutions.

The Internet of Things

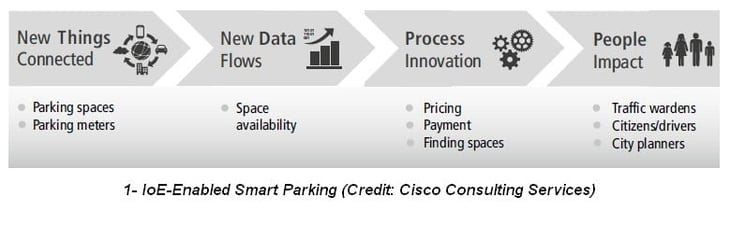

Without spending a lot of space on explaining a definition of “The Internet of Things” (IoT), let’s use a simple definition of “a networked connection of physical objects.” While the term has existed for nearly twenty years, IoT was connecting less than 1% of all devices worldwide as recently as 2015. While most of us are familiar with the devices like home security systems, smart thermostats and smart speakers, there is a large universe of objects in the process of getting connected that will change the way we interact with them. In part, it is because they are interacting amongst themselves as well! Here is a simple example of how parking in a city would change with IoT:

As you can see from the diagram, IoT is not just connecting “things,” IoT is also using the intelligence gathered to improve services or information quality for people. IoT can be used to drive an app that a driver can use to find parking, measure capacity utilization by the time of day to improve planning, determine dynamic pricing, etc.

What is the impact of IoT on logistics?

IoT is already transforming the warehouse, often OUTSIDE of it in related businesses that are connected to the warehouse or providing a mission-critical service for it. Here is a short list from a study published by DHL and Cisco in 2015:

- Traffic and Fleet Management – one area where IoT is already widely deployed, is in managing fleets – autos, trucks, taxis and even city buses. Trucks are now used more efficiently than ever by monitoring locations, identifying spare capacity, reporting delays and reducing pollution with optimized routing. One example is the Port of Hamburg (Germany), deploying 300 roadway and waterway sensors to monitor traffic, reduce the impact on local citizens by predicting when bridges will be closed for ship traffic, and more.

- Resource and Energy Monitoring – Think of a “Nest” thermostat for your facility. Utilities, cities, energy companies all are taking advantage of these technologies. The example in the paper cites an Israeli water company, Hagihon, deploying in-ground sensors that track water pressure and flow. Other sensors can detect leaks and cracks and pinpoint their location. For the warehouse, imagine a similar system monitoring and adjusting temperature, lighting and checking on moving systems (like conveyors) for mechanical problems, stress, etc.

- Connected Production Floor – similar to the resource monitoring, sensing systems that are prone to fail is a key application, as is preventative maintenance. Continental Tire leverage IoT top solve some production problems by integrating carrying carts of components with their inventory system via Wi-Fi that locates all of them on a map of the facility, reducing downtime and lost inventory.

Other areas impacted included Employee and Equipment Monitoring, Physical Security, Health Monitoring, and more.

Software

There is almost no discussion about the future of any part of your business that does not involve software. It’s the circulatory system of everything now, and you need to recognize that it is a required area of basic knowledge both to understand the opportunities it provides AND the threats that come from getting it wrong.

Convergence is now taking place between Warehouse Management Systems (WMS), Transport Management Systems (TMS) and Enterprise Resource Planning Systems (ERP). According to a 2015 White Paper from Supply Chain Services (“Future of Warehouse Efficiency”), these systems are becoming more responsive to real-time situations, like delaying the release of an order to a pick zone if that zone is still congested from a previous wave, for example. However, a large majority of businesses (70%) are not taking advantage of the capabilities which are offered by software designed for their specific solution area. The “future” aspect here is that over 50% of those lagging are planning to close the gap by investing to get caught up – a threat to competitors in their industry who might be tempted to avoid taking a leap.

From “Warehouse” to “Distribution Center” to “Omni-Channel DC”

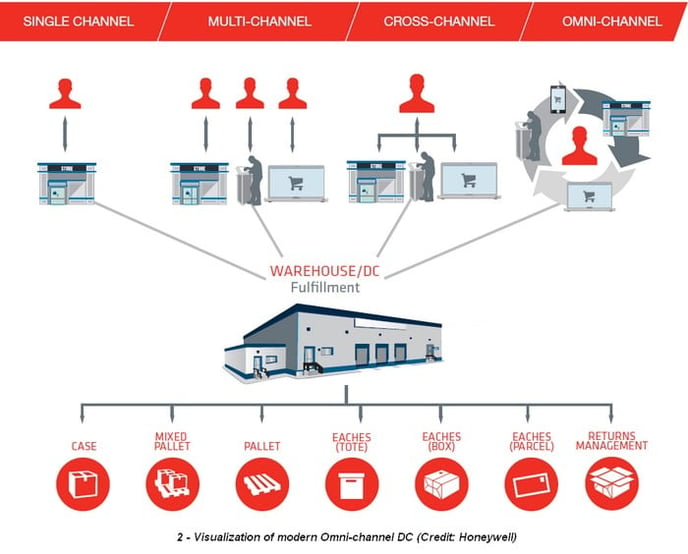

The last 20 years saw the evolution of traditional warehouses into Distribution Centers (DC). While this was something of a “revolution” for traditional retailers and even more so for manufacturer’s who ventured into direct-to-customer sales, E-commerce operations were largely a copy of the operations run by big catalog companies since the 1980’s. Moving beyond the initial transformation driven by the internet, software, transportation and Auto-ID advancements are turning almost any warehouse space into an “Omni-Channel Distribution Center”.

This graphic from Honeywell illustrates both the transformation over time from single to omnichannel and the complex mix of processes a modern DC is expected to support:

Is your inventory connected in real-time to your customer website? Can a customer see when their products have been shipped and track them? Is your incoming inventory from overseas factory included in your available or back ordered inventory? It is not just the diversification of space utilization and equipment improvements, but also the software that is critical to make this work for you. The common theme in all of this is one of improving customer satisfaction.

Resource Scarcity – Finding More Space and People

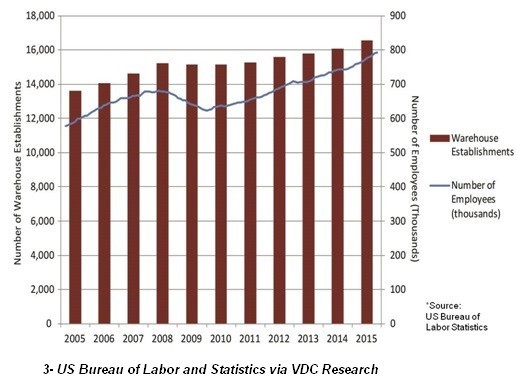

Finally, one more critical topic that flies under the radar is the scarcity of both space and people. While the news focuses on the decline of retail jobs, shuttered store-fronts and even entire malls becoming ghost-towns, this apparent “decline” in retail somewhat mirrors the increased employment in DCs and the rapid expansion of space. Even retailers in the news for giving up storefront space are at the same time expanding their warehouse space as more and more of their sales move from the storefront to the online channel.

Our annual Customer Satisfaction Survey also confirms “space utilization” as our customer's most important problem to solve. Naturally, adding more space is not the most cost-efficient approach, and in some distribution hubs, the cost per square foot is increasing rapidly as more business look to be part of the clusters that have already established themselves with an experienced workforce and shorter distances to the transportation “hubs” of private shipping companies.

What does the pressure on space and labor mean for the future DC? Here are some key strategies from VDC Research for managing growth in an environment of increasingly constrained resources:

- Material Handling Solutions: Automation systems including ASRS and Order sortation systems.

- Data Capture: Real-time visibility with data capture technologies such as imaging solutions for quality checks, barcode scanning, and dimensioning systems for cubing of the items for high-density storage and transportation.

- Wearables: Augmented reality and voice technology are growing to support a larger variety of processes.

- Robotics & AGV: Greater automation, solutions for palletizing, depalletizing, ASRS, and AGVs are being deployed widely around the world. Look for the introduction of individual item picking/packing robots too (which we recently saw at MODEX).

The Future Happens in Steps – Take One Today

As we stated up front, the “future” is already here – but you might not be fully participating yet. Rather than pull together a committee and give them a massive project of planning out the perfect transition for your business to happen all at once, take a look around today and identify some small steps you can take now while keeping the other foot in the “planning” space.

Here are some ways for you to take some baby steps today:

- Look at your DC on a process-by-process basis. Gemba walks, staff feedback and KPI development will highlight easier, low-cost areas to focus on first.

- Start with areas that have the most people – the largest variable costs under your roof often have the lowest hanging fruit for modernization.

- Get a consultant – bringing in a fresh set of eyes who might have a better idea of what your competitors are doing AND can give you an honest overview of your current portfolio of software, equipment, and