Have you spent any time observing the activity on your dock recently? How do you feel about the way it works and the share of cost it takes in your operations? Are you tracking the cost? Well, given that nearly every operations facility is a “cost center” on your company’s P&L, you should be looking at your cost structure for each of our main “Process Areas” like Receiving, Picking, Packing, Shipping, etc. While there are a lot of factors that go into generating the cost model for each of your processes, two areas in particular - Receiving and Shipping - are particularly dependent on the design of your dock and the equipment deployed to support it.

Have you spent any time observing the activity on your dock recently? How do you feel about the way it works and the share of cost it takes in your operations? Are you tracking the cost? Well, given that nearly every operations facility is a “cost center” on your company’s P&L, you should be looking at your cost structure for each of our main “Process Areas” like Receiving, Picking, Packing, Shipping, etc. While there are a lot of factors that go into generating the cost model for each of your processes, two areas in particular - Receiving and Shipping - are particularly dependent on the design of your dock and the equipment deployed to support it.

Your dock area is the most critical part of your entire warehouse. What other part of your warehouse can you say that every single product coming in or out passes through? That is why it is so critical – because a poorly designed dock area can make the rest of your facility inefficient by becoming a logjam or a source of errors that are amplified into the processes that depend on it.

But what goes into good “Dock Design”? Like most other parts of your warehouse infrastructure, a design based on the optimized actual process you use for the business will generate the biggest and fastest ROI, so it always pays to start with your existing process, break it down to see if it’s working for you or not and update it to meet a more optimal standard you want to achieve. We’re taking a deeper look at Dock Design and the different variables you may want consider when rethinking your own space. Today, let’s start with one aspect you don’t always have real control over what your facility has – the physical docks themselves and the bays. Next week we’ll get into specific design, layout and equipment choices that ensure you can optimize your Dock performance.

One Dock or Two? Four Scenarios:

One key aspect that is sometimes out of your control is the number of docks and bays you have. If you just signed your contract for leasing an existing facility or are firmly entrenched in an existing one, then you will need to focus on what your options are for the docks you have – or don’t have. There are four typical models that exist for docks, and if you are locked into a facility already, then for this area it makes more sense to evolve your processes to make the best use of the infrastructure you have. Which one looks like your facility?

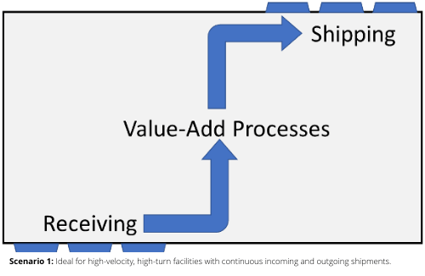

1. Two Docks, Opposite Side of Facility

For many facilities with high velocity turnaround or large bulk storage, this is ideal because it allows you to design a single continuous flow through the warehouse and allows you to schedule receiving and shipping at whatever times work best for you  or your shipping partners and vendors. Having exclusive space for both processes has many obvious advantages, but can also lead to overall less efficient use of space if it means doubling up on equipment normally shared by Receiving and Shipping and having two separate locations where pallets are staged and broken down.

or your shipping partners and vendors. Having exclusive space for both processes has many obvious advantages, but can also lead to overall less efficient use of space if it means doubling up on equipment normally shared by Receiving and Shipping and having two separate locations where pallets are staged and broken down.

Pros: Creates distinct and separate dock areas of incoming and outgoing shipments, allowing 24/7 access without overlap or conflict between Receiving and Shipping. Ideal for fast-paced, high-velocity facilities (i.e. Grocery Distribution) where incoming goods are often shipped out again within 24 hours.

Cons: Forces your workflow to transit across the warehouse where it may not be optimal for some businesses. Also requires more security and additional considerations for heating and cooling where relevant. Potentially larger share of total space taken by two separate docks and possible duplication of equipment (i.e. label printers & scanners, extendable conveyors, etc.). Also makes cross-docking difficult, if not unproductive. If both docks are lined up on opposite sides of the facility however, this might be easier.

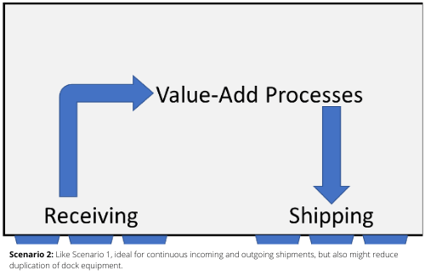

2. Two Docks, Same Side of Facility

This scenario is not normally something that is intentional for a single facility, but most likely built with the intention of the building housing two separate operations or businesses. But where it does exist, it has some of the same advantages and disadvantages as Scenario 1. Depending on the number of bays needed/available and the space between the two docks, there  is some of the same potential for duplication of equipment that otherwise could be shared between Receiving and Shipping. However, like the previous scenario, a fast-moving environment where incoming and outgoing shipments may not be regularly scheduled and will frequently overlap will make good use of this dock configuration.

is some of the same potential for duplication of equipment that otherwise could be shared between Receiving and Shipping. However, like the previous scenario, a fast-moving environment where incoming and outgoing shipments may not be regularly scheduled and will frequently overlap will make good use of this dock configuration.

Pros: Like Scenario 1, creates distinct and separate dock areas of incoming and outgoing shipments, allowing 24/7 access without overlap or conflict between Receiving and Shipping. Ideal for fast-paced, high-velocity facilities or single-shift facilities where significant staging space is required for one or both of the processes depending on having access to the docks. Much easier to design efficient cross-docking processes than Scenario 1 as well.

Cons: Depending on the distance and separate between docks, may also require more security and additional considerations for heating and cooling where relevant. Will also use larger share of total space with two separate docks and possible duplication of equipment (i.e. label printers & scanners, extendable conveyors, etc.). Where cross-docking is important, a larger distance between the two could result in more wasted space.

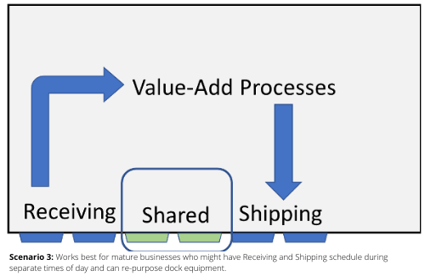

3. One Dock, Shared Bays

Where only one dock is in play, the number of bays will make a difference too. For example, if the facility only has 2-3 bays and your optimal number of bays for Receiving and Shipping are both 2-3 bays, then you have a potentially huge problem. How do smart process-driven businesses work with that? For some, it will mean scheduling receiving in the morning and shipping in the evening. A fast-paced consumer business driven by E-Commerce can easily schedule pickup by the shippers in the afternoon or evening (depending on the proximity of their collection hubs), and have the shippers empty trucks pull up to be loaded in the afternoon ready to drive away to the hub at the contracted deadline. They will also arrange to have Receiving done in the morning (easier with full containers designated for that facility) so that not only is Receiving completed often by 9am and the bays available for shipping, but also ensuring any replenishment for new orders can be available for picking early in the day and ready to be shipped right out again in the evening.

This type of facility has some juggling required to make it work, but can have a lot of upside in terms of how it will make your business focus on very crisp processes that are time-driven and inter-dependent in a way that may be advantageous. It also means that core equipment like scanner/printer stations and extendable conveyors can be re-purposed for incoming and outgoing shipments without having to be moved around the facility.

Pros: This scenario is well-suited to a business that can schedule its Receiving and Shipping at different times of day, which then permits the re-purposing of key equipment and infrastructure for both processes rather than having wasteful duplication. It also minimizes the total percentage of the facility space being used for the dock (which in turn demands efficient use of the dock!), freeing up the entire warehouse for other value-added processes and storage and minimizes the potential security issues that a two dock facility would have. This scenario, paired with high bay reserve storage and a mezzanine level area for picking, processing and packing, might potentially be the most efficient space per square foot for businesses that can manage the use of the bays by time of day.

Cons: Any fast-moving, high-velocity business with minimal storage time and frequent deliveries and shipments will find themselves looking for new space rather than be able to make this work. The loading/parking area outside the facility might require a full-time traffic manager for the potential congestion. In addition, even businesses that see most of the benefits from this type of dock will find that cross-docking is not the breeze it normally should be because incoming items will need to be set aside in some additional reserved space and sit there until an empty truck is allowed to come in during their designated time slot.

4. One Dock, Shared and Dedicated Bays

Finally, one additional scenario that is similar to number 3 is the single dock, but with enough bays to handle both incoming and outgoing shipments at the same time. In some ways this is perhaps the ideal setup for most facilities, because it allows management the flexibility to create and update their preferred configuration as the business evolves. You can close down two bays in the middle and create two docks like Scenario 2 (and even build workspace or racking in that space if needed), close off half of them to provide a set-up like Scenario 3, and then open one additional one each time the growth of the business justifies it, or during peak season when volumes could be double or triple the average volume. The other possibility is that each process could have its own dedicated bays for continuous use and “share” the additional one where scheduling of incoming and outgoing shipments might determine the use of them by time of day.

Pros: Maximum flexibility for a facility manager – essentially creating an opportunity to replicate Scenarios 2 and 3 if the business evolves to require that, or if seasonality dictates a different configuration to handle large volume changes. For this scenario, it also means the potential to allow for a hybrid model where some fixed scheduling of incoming and outgoing shipments can be managed for some bays and others are dedicated for either Receiving or Shipping if there is continuous arrival and departures during the day. Peak season? Staff up your Receiving team, open up two more bays and see the turns go up without any drop-off in performance or logjams on the Receiving dock.

Cons: For the evolved, mature business with great process control and measurement, this type of facility might be just wasteful if, for example, it comes with eight bays and you only ever need 3-4 at most. While you don’t need to use the others of course, the unused dock space will not be as user-friendly to build out your other processes that might use that space, be it for racking, workstations, etc. It may seem like a small issue, but the best warehouses know how to use every inch and a non-standard “wall” of closed bay doors will appear to be wasteful. It also means additional heating or cooling coming from those bays not being insulated like the standard walls, etc.

Which One Works For You?

How is your facility configure for Receiving Docks and Loading Docks? Do any of the scenarios above resonate with your experience? There are many other possible configurations, but we tried to cover the scenarios you will most likely encounter here. If you have some experience relates to any of these scenarios and would like to share it we’d love to hear from you and to hear how you managed through it as well. Success stories and tough lessons learned are equally welcome.

Next week we will go beyond the type of facility and get into the factors to consider in laying out and equipping your docks for maximum productivity.

See something? Say something! We'd love to hear about your own facility and the challenges you've solved on your docks.

See something? Say something! We'd love to hear about your own facility and the challenges you've solved on your docks.