Last month, we published Part I of this article, where we talked about making that transition from “freewheeling inventor” to “process-driven listener”. Basically, it is about being more systematic in how you collect the data and insights that lead to more relevance in your new products. This is hardest for the business which was started from a single brilliant idea that succeeded, because it is not uncommon for the small manufacturer to not really understand WHY their initial product succeeded. Play-Doh, the ubiquitous colorful molding clay of everyone’s youth, was originally created in the 1930’s as a wallpaper cleaner. Success is great, but if you started out intending to be an innovator in the cleaning products business but all of your customers are under five years old, where do you go next?

Today we’ll walk through a few different defined processes that are known to us, as well as provide an opinion on what we think you may or may not find useful. Every business is unique in regards to what will work for its industry, target audience and internal culture. Best to map a process to the strengths of your culture than to try to bend your culture to someone else’s process!

The Industry “Standard” That May Not Be for You

First, let’s take a peek at one of the typical standard frameworks common with larger, established manufacturers, and then share why this might not be right for many of the smaller entrepreneur shops out there today. Referred to as the New Product Development, or NPD, framework, it has eight important components (and an unimaginative name):

First, let’s take a peek at one of the typical standard frameworks common with larger, established manufacturers, and then share why this might not be right for many of the smaller entrepreneur shops out there today. Referred to as the New Product Development, or NPD, framework, it has eight important components (and an unimaginative name):

- Idea generation - is defined as “the continuous and systematic quest for new product opportunities, including updating or changing an existing product.” This is something that belongs in ANY process you choose for your business.

- Idea screening – using an objective set of considerations, unworkable ideas need to be taken out of consideration. This too can be embedded into the idea generation to some degree.

- Concept development and testing - is a vital element here. This is the stage where the cold, objective internal analysis of step two is replaced by the more unpredictable customer opinion. The idea or product concept should be tested on a true customer base. Feedback can then be leveraged to adjust and further develop the concept accordingly.

- Market Strategy/Business Analysis - is comprised of four P's, which are product, price, promotion, and placement.

- Product: The service or good that's been intended for the target audience.

- Price: Pricing decisions affect everything; margins, demand, and market strategy.

- Promotion: The goals of promotion are to illustrate the value of the product to the target audience, using advertisements, public relations, and marketing campaigns.

- Placement: Since in today's digital economy the customer is generally engaged and converted on the internet, this must be considered the primary channel for decision-making. The product’s location provides an answer to how it will be fulfilled (stores, shipping from own warehouse, shipping from the distributor, etc.)

- Feasibility Analysis/Studies - provide information that is critical to the product's success. It requires organizing groups to test a prototype, then evaluate it in a test panel. It is intended to measure the target market's level of interest and desired features, as well as determine the potential for attainable and viable profit for the company while satisfying a real demand from the audience.

- Product Technical Design/Product Development - consists of turning that prototype or concept into a workable offering, solving any technical hurdles and coordinating with the other departments involved with the launch.

- Test Marketing, or Market Testing - is more robust than beta testing in that the prototype product and whole marketing plan, not individual segments, are evaluated - from marketing angle and message to packaging to advertising to distribution. Testing the entire package before launch provides a stronger validation of the product before a full go-to-market investment is made.

- Commercialization - the product is introduced to the target market, using all the data obtained throughout the previous seven stages of this approach to produce, market and distribute the final product to or through the relevant channels.

Sounds exciting? Not so much. The problem with this process for a small manufacturer is that it requires a large portfolio of skills that typically won’t exist in your business, or require an even larger budget to “rent” them from a team of consultants for the product, making it feel both unwieldy and inherently risky.

Different Processes for Different Needs – Even Fuzzy Needs

Instead here are a couple of different options we like for the little guys. First, there is not just ONE process that will work for everyone. You need to design your own, but obviously it makes sense to utilize steps and sub-processes that fit with your business and industry. There are a number of documented methods you can use or borrow from.

Fuzzy Front End

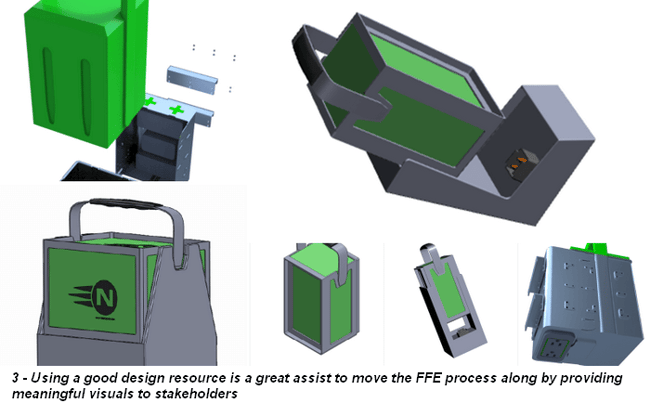

Some frameworks, like the “Fuzzy Front End” framework (FFE), give your team perhaps the most flexibility in regards to the order of getting things done. FFE defines the steps that should be followed but leave it up to your team to decide which order is the most sensible for the specific product being developed. One highlight of this process is the rapid proto-typing aspect involved, where concepts considered potentially relevant are quickly proto-typed in a quick and dirty approach to test the concept rather than a market-ready sample that would otherwise be tested with a potential audience. One way to make this more effective is to have a good design resource – not just to do the technical drawings but who could create something closer to the “artist’s rendition” version that would look consumer ready and even place it into context (i.e. show it in the use scenario it was designed for). For those of you familiar with our Nucleus battery, here are a few early design concepts that were used to keep everyone on the same page in regards to visualizing what we were trying to accomplish:

Some frameworks, like the “Fuzzy Front End” framework (FFE), give your team perhaps the most flexibility in regards to the order of getting things done. FFE defines the steps that should be followed but leave it up to your team to decide which order is the most sensible for the specific product being developed. One highlight of this process is the rapid proto-typing aspect involved, where concepts considered potentially relevant are quickly proto-typed in a quick and dirty approach to test the concept rather than a market-ready sample that would otherwise be tested with a potential audience. One way to make this more effective is to have a good design resource – not just to do the technical drawings but who could create something closer to the “artist’s rendition” version that would look consumer ready and even place it into context (i.e. show it in the use scenario it was designed for). For those of you familiar with our Nucleus battery, here are a few early design concepts that were used to keep everyone on the same page in regards to visualizing what we were trying to accomplish:

Design Thinking

Another popular one is “Design Thinking”, which is a series of iterative steps designed to work in a specific order that is intended to promote greater creativity and collaboration. It consists of five steps, each is easy to understand, but also somewhat high-level for the specific needs of some industries. But even then, it has the potential for bringing out a larger collection of ideas and potential unexpected gems if the team involved is nurtured and empowered accordingly. The five steps for Design Thinking are:

- Empathize – A method to learn more about the problem from multiple perspectives. This could include leveraging research (ongoing, one-off, customer/transaction data analytics, etc), field visits, competitive research, etc. One key thing to avoid leaving out is to also include prospects who never bought or lapsed customers because very often their DIS-satisfaction will generate more insights than your happy users will.

- Define - Identify the scope and true nature of the problem. The key here is to start with the PROBLEM. Too many small manufacturers start with the IDEA, then either look for a problem to solve or are surprised later when the market yawns at their new creation. If you did your research right, you would be including questions like “Why did they NOT buy our existing product(s)?” and “What does our existing product NOT do?”, etc. to get at what the problem is. The truth is that many of your customers aren’t even aware they have a problem – it is up to you to identify, describe and educate what it is (or will be).

- Ideate - Brainstorm solutions to the problem. Ideas come much easier when the team has a defined universe to work within. “Let’s get some ideas on how to improve the post-picking sorting process” is a much more attainable goal than “Let’s brainstorm ways to improve efficiency in the warehouse”. Brainstorming itself is not always easy. Long sessions can be fruitless and create a lot of grumpiness among a team. Having a designated moderator, especially from outside the team (or business) is often a good way to keep a better perspective. And it often pays to let people vent with silly ideas and humor. Many good ideas sometimes started with a laugh. Did you know that twenty years before Gillette came out with the Mach 3 razor, Saturday Night Live parodied it with the “Triple Trac Razor” in the 70’s (and again in 2000 with the “Platinum Mach 14”)?

- Prototype - Weed out unworkable or impractical solutions. This step seems obvious, and one would think it unnecessary if the previous steps were done with some diligence, but it’s important because you don’t want to tighten the filter of the “Ideate” process too much so that no one feels confident with some of the more original ideas, and you can’t always account for specific unknowns in the brainstorming. For example, an assumption about the ability of a specific material intended for use may have been wrong, or the only way to produce it was with a 3D printer making it unsuitable for mass production, etc.

- Test - Solicit feedback. Finally, the feedback part of the process should close the loop with the initial research. If customer research identified something that was a specific “problem” (known or otherwise), then the new products – even in a conceptual stage – should resonate with them. And even when it does, there will be improvements that might come from the feedback that will further validate the potential of the idea.

Time to Mold Your Own Process For Your Business

If all of this sounds like taking out a couple of tubs of Play-Doh and creating something you like, you might be on to something. Mix and match elements that work for your business – those that represent an existing strength for your business should be there (in part because it will come easy for your team), and those that are definite weaknesses that need to be evaluated if they are necessary. If there are necessary, get help for them (i.e. a good design resource with technical skills or a great project manager that can herd all your cats for you!).