What is Lean?

Essentially, “Lean” is centered on preserving value with less work which is a difficult task in a complex business with many processes and employees. A Lean environment requires a different style of management, style of leadership, performance measurements, organizational structures, thinking process and a different culture. It took Toyota over twenty years to develop what we now call Toyota Production System. (TPS). You cannot expect long term results without properly investing in training and not rushing the implementation.

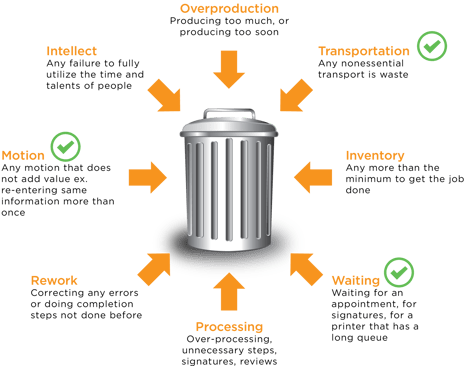

Lean Focuses on the Elimination of Waste in a Process

Reduce motion, waiting and transport wastes by up to 50% in your manufacturing with mobile power.

At Newcastle Systems, we provide equipment for any business using a lean methodology to make immediate improvements with new technology for the workplace to go mobile. Establishment of lean manufacturing is a continually evolving process. There is no end-point where you can step back and declare that you're done and your company is now a lean, mean production machine. Room for improvement and areas in which waste can be reduced will always exist, but you can keep those issues to a minimum by being diligent and vigilant when it comes to evaluating all the steps involved in your production efforts.

Think about where you have waste. We all have it. |

|

|

|

Mobile Power can help reduce waste. Here's how: |

|

|

EFFICIENT

|

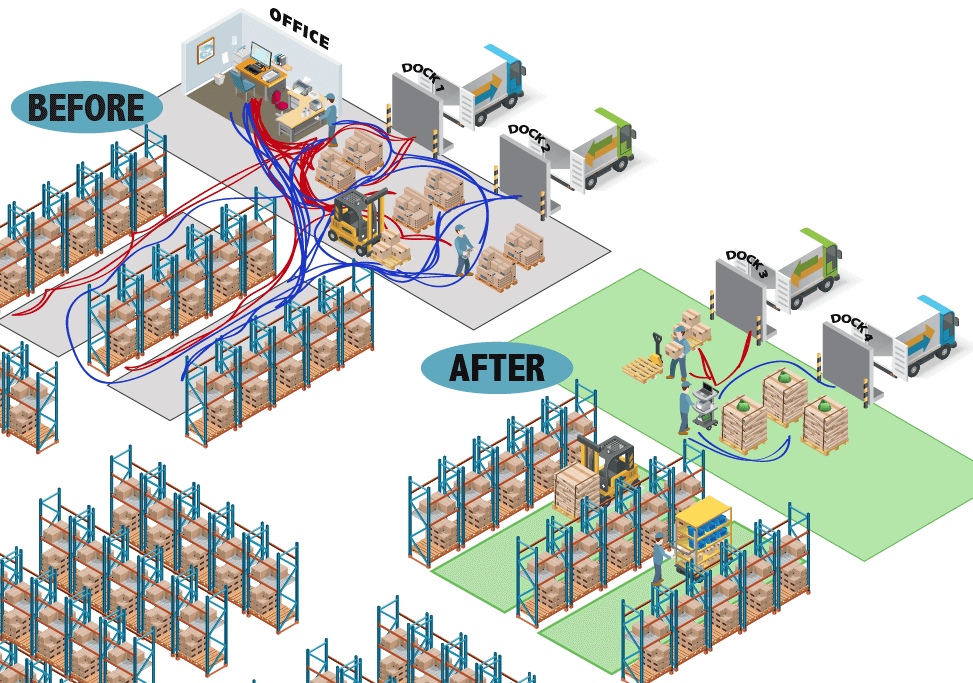

Minimizing touches is key to successful warehouses and distribution centers. Eliminate moving goods to a stationary printer for labeling and allow loads to be processed at the dock. |

MEANINGFUL

|

Workers walking to and from fixed printers or computers can be as much as 50% in some organizations. They can essentially double their productivity when this motion is eliminated. |

|

LESS

|

Anyone waiting for work from "upstream" is wasteful. Quickly eliminate material handlers waiting for inbound goods to put away, workers waiting for a shared printer or PC and/or shippers waiting for packed goods. |

“We’ve increased worker productivity by 20% and reduced overtime costs by more than $40,000 annually by deploying Newcastle carts in our receiving area.”

- Richard E., Industrial Engineer

Learn More about Lean Manufacturing

Lean Manufacturing: 3 Critical Principles for Improving Productivity

If Lean is so Great, Why Doesn't Everyone Do It?

18 Lean Manufacturing Quotes (#5 is Amazing)

Lean Manufacturing Consultants, The Real Story [infographic]