For many organizations, handling reverse logistics can be challenging. If you think about it, most supply chains are created to get products from point A to point B, not bring them back in the other direction.

Online ordering has made shopping so simple that customers expect an equally hassle-free returns process. While product returns might be one of the costs of doing business, how you handle the 5 Rs of reverse logistics can impact how much this process will affect your company’s overall results.

What is Reverse Logistics?

Just as it sounds, reverse logistics is managing the supply chain in reverse. Goods move from customers back to the warehouse, sellers, or manufacturers. The process begins with the customer, who decides to return a product that they’ve purchased for a refund, credit, repair, or replacement. It can also include customers who return products for recycling, resale, or refurbishing to get credit on a new purchase.

Just as it sounds, reverse logistics is managing the supply chain in reverse. Goods move from customers back to the warehouse, sellers, or manufacturers. The process begins with the customer, who decides to return a product that they’ve purchased for a refund, credit, repair, or replacement. It can also include customers who return products for recycling, resale, or refurbishing to get credit on a new purchase.

Why Reverse Logistics Needs Your Attention

Reverse logistics is used extensively, with the goals of retaining customer loyalty and recouping value from returned products. Because of the growth of eCommerce, returns are now valued at nearly a trillion dollars annually worldwide. Roughly 30% of items ordered online are returned, compared to just 10% on purchases of in-store items.

Globally, companies are transforming the way they address the customer experience and waste. And the supply chain is a significant piece of these initiatives. People are more likely to buy from a company that provides a hassle-free returns process. Likewise, consumers care about the environment and don’t want to learn that products are ending up in landfills or otherwise going to waste.

When items in the supply chain travel in reverse order, your organization has to figure out a way to handle those products. The five Rs of reverse logistics are returns, reselling, repairs, replacements, and recycling. The processes and solutions you apply to each of these can help your business improve its results.

Managing the 5 Rs of Reverse Logistics

Many organizations associate reverse logistics with simply handling returns. But it can be much broader than that. As the supply chain becomes more complex, you can optimize this part of the process by managing the 5 Rs of reverse logistics.

1. Returns and Exchanges

The best way to deal with product returns and exchanges is to avoid them in the first place. Some of the ways you can do this include:

- Sell high-quality products

- Create clear product descriptions

- Avoid shipping the wrong items

- Establish processes to prevent product damage during storage or shipment

Once you’ve done everything possible to prevent returns and exchanges, it’s important to provide customers with a pain-free process to return or exchange items when necessary. Depending on the size and scope of your operation, you may wish to craft a reasonable return policy.

Once you’ve done everything possible to prevent returns and exchanges, it’s important to provide customers with a pain-free process to return or exchange items when necessary. Depending on the size and scope of your operation, you may wish to craft a reasonable return policy.

The goal is generally to balance the need to satisfy customers against the hassle and cost associated with merchandise returns. Big companies, like Amazon and Home Depot, can afford to have incredibly liberal return policies. Small businesses, on the other hand, don’t have this luxury.

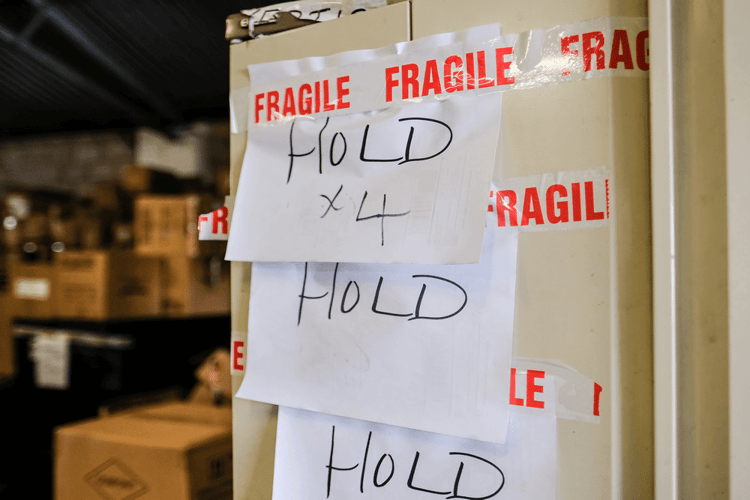

Whatever your policy, the key to handling returns is to have processes in place for receiving, inspecting, and testing products. This also involves tracking systems to keep tabs on where products are as they come back into the system.

2. Reselling Returned Products

Just because one customer doesn’t want a product, that doesn’t mean it won’t be treasured by someone else. As a business, you can add to your bottom line by processing and selling returned products.

In the U.S. alone, the secondary market is worth over $15 billion annually. Just think of the companies that have leveraged this business for additional profits. For example, Amazon has its Amazon Warehouse, which brings in millions annually.

Most products (around 95%) get returned because customers aren’t satisfied with them, not because there is something wrong with the item. The first step to reselling returned products is to tag them and get them back in the system. Then, they need to be tested, repackaged, and returned to inventory for resale.

3. Repairs

Some customers just want a broken item fixed and returned instead of a replacement. Even if a customer doesn’t want the item back, you can often lower the overall cost of returns by making repairs on-site and getting the item back into circulation.

To manage repairs, some companies set up a field repair operations center, where products can be quickly inspected, fixed, and sent back into the field. If the issue was minor, the product could be sold as “like-new” or “reconditioned.” Products with flaws can be repaired or marked as such and discounted according to the defects. Then, those items would also be repackaged and listed for sale, generally at reduced prices.

4. Replacements

Some consumers just want the same product but a different version. Maybe those shoes were a bit too tight or the wrong shade of blue. Or the gasket was made to fit a different model, and they need the correct one.

Some consumers just want the same product but a different version. Maybe those shoes were a bit too tight or the wrong shade of blue. Or the gasket was made to fit a different model, and they need the correct one.

Giving customers seamless return and exchange options can improve the customer experience, increase retention rates, and boost your bottom line results. Some sellers, like Kohl’s and Zappos, make printing pre-paid return labels simple.

When returning something to Amazon or Zappos, the company will ship the customer’s replacement as soon as it receives notification that the return is on the way. Using a robust solution like a warehouse management system (WMS) can help your company manage this process and keep track of incoming and outgoing inventory.

5. Recycling and Disposal

Consumers are more interested in making sustainable choices, and they’re letting their wallets speak for them. Companies are listening by making sustainability a higher priority. According to research by McKinsey, one in four customers says they are focusing more on environmental issues and will pay attention to this when shopping.

Beyond keeping your customers happy by properly recycling products and packaging, your business can also reduce costs. For example, Apple recovered about $40 million in 2015 alone with its revolutionary recycling program for its products. And, in many states, recycling electronics is now a legal requirement. Other brands, like PepsiCo and Proctor & Gamble, are offering reusable packaging that consumers can return for reuse. When transportation and logistics companies drop off products, they can pick up the used packaging for return to the warehouse.

Whether items require recycling or disposal, they are still brought back into the system. Having a way to track them reliably can give your company the data it needs to make intelligent business decisions about the processes it uses.

Reverse logistics is a vital function in the modern supply chain. With the continuing pressure on retailers and their vendors to build a positive customer experience, returns will continue to be a common piece of the equation. It is for this reason that warehouses and third-party logistics companies are turning to technology solutions to enable more efficient reverse logistics management with less hassle, stress, and costs.